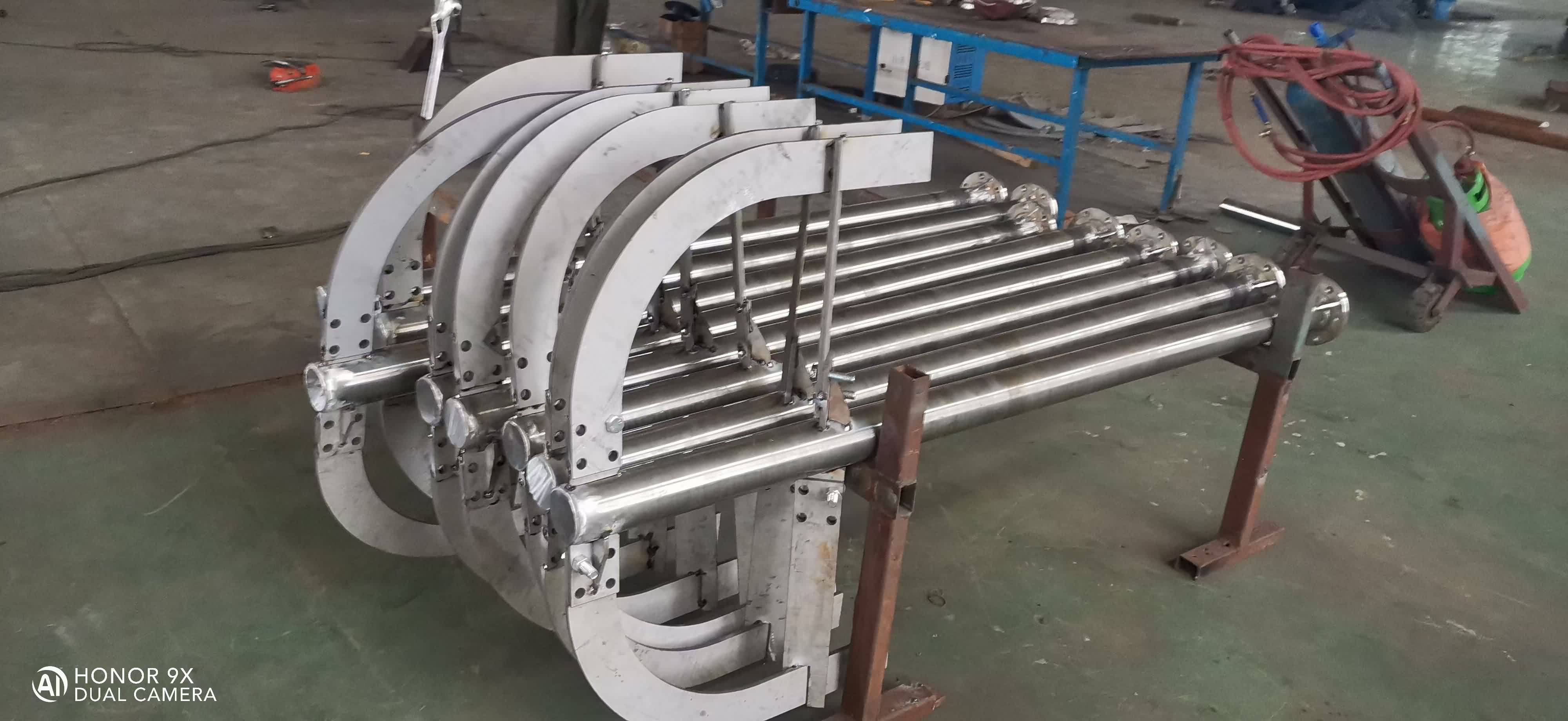

二次包络蜗轮副详细介绍

二次包络蜗轮副的承载能力一般的是设计能力的百分之四十到百分之五十。由于等分的精度太差,蜗轮副的使用寿命为设计能力的百分之五十五,噪音曾大,安装的位置度不能保证,啮合间隙无法保证,需要与蜗杆跑和才能使用。涡轮蜗杆不能互换等等。使用平面二次包络蜗轮滚刀加工蜗轮。使用的方法与加工普通蜗轮的调整机床一样,可以按照刀具的使用说明书的指导,十分方便的加工出标准包络蜗轮来,蜗轮容易测定(刀具生产厂提供在线的检测样板和测试方法),蜗轮的分度精度好精度,齿形角的精度有保证,加工效率与一般的蜗轮加工基本一致。与蜗杆的配合精度高,互换性好,可以分别加工,各自控制精度,不用跑和,直接装配。装配的间隙小,包络蜗轮副的承载能力在未磨合前就可以达到设计能力的百分之八十五以上。使用寿命可以达到设计能力的百分之九十五。使用的工作热小,噪音少等。

The two bearing capacity envelope worm gear is generally a design capacity of forty percent to fifty percent. The equal accuracy is poor, the service life of worm pair is fifty-five percent of the design capacity, the noise had large, installation position accuracy can not be guaranteed, the meshing clearance can not be guaranteed, and the worm to run and to use. Worm can't exchange etc.. Use the plane enveloping worm hob machining worm gear two. Adjustment of machine tool and processing common worm wheel, can be in accordance with the instructions of the cutter guide, very convenient processing standard enveloping worm, worm gear easy determination (detection model and online test method for providing tool manufacturing plant), indexing accuracy good precision worm gear, tooth profile angle accuracy guaranteed, processing efficiency is consistent with the worm gear processing general. With the high precision of the worm, good interchangeability, can be respectively processed, their control precision, don't run and, direct assembly. Assembly of the small gap, bearing capacity envelope worm gear in not running before they can reach the design capacity of more than eighty-five percent. The service life can reach to ninety-five percent of design capacity. Using the work of heat is small, less noise.

二次包络蜗轮副:http://www.yjcd.net/article/20140212111342.html